MIRAMAS, France ― Automakers are under relentless pressure to become ever more efficient at reducing both fuel consumption and emissions ratings. But at the same time, customers expect an increasing level of safety, technology and luxury. This has led to some truly inventive thinking from manufacturers – from the use of lightweight materials, to advanced aerodynamics and drive management systems that can consider the route ahead of you and adapt shift and throttle responses accordingly.

BMW invited us to their Miramas Test Facility in the south of France, to have an advance look at some of their latest technology.

CFRP Driveshaft

Lotus's Colin Chapman knew that to "go faster, you add lightness". Carbon Fibre technology is the modern day answer to the eternal quest for lightness: 30 per cent lighter than aluminum and 50 per cent lighter than steel, it's ideal for reducing vehicle weight while adding stiffness.

BMW has had the jump on carbon fibre reinforced plastic (CFRP) technology - bringing the costs down by manufacturing it themselves - with the introduction of their all-electric "i" brand. It was only a matter of time before they extended the use of this light, yet incredibly strong material throughout the rest of their lineup.

One of the most interesting items on display was a driveshaft, made entirely from CFRP - which will be introduced for the first time in the new BMW M3 sedan and M4 Coupe.

CFRP is not only extremely light - it's also renowned for its stiffness. The strength allows the driveshaft to be produced in one single component – without the weight-adding centre bearing of most conventional units.

Not only does this reduce the shaft's weight by 40 per cent, the overall reduction in rotating mass results in much quicker engine response and faster acceleration.

Engine Thermal Management

Developed for the new i8 electric sports car – engine thermal management will probably spread throughout the rest of the BMW lineup.

Although engines really love to breathe cool air, they function best when their body parts are kept warm. According to BMW's Intelligent Energy Management project leader, engineer Felix Schedel, engines run their most efficiently and economically when hot – yet the nature of most commutes rarely gives them the opportunity to reach that peak temperature. "The warmer the engine is at start up, the better the fuel economy will be".

Their solution was an "engine capsule" or system of various blankets formed from lightweight thermoplastic. Created of varying thicknesses depending on the job they do, these blankets cover the sides, bottom, turbo, exhaust and the gearbox and help delay the engine's cool down.

Turning over the various components in our hands, we could see the heat-reflecting foil of the thinner pieces that wrap the exhaust manifolds, with thicker, spongier capsules that encased the cooler parts of the engine.

Not only does the engine capsule help keep it at optimum temperature but it also helps reduce noise and vibration.

Laser Headlights

Between BMW and Audi, it's been a very close race to see who will be the first to market a vehicle boasting laser beam headlights. While Audi recently showed off their laser-equipped Audi Sport Quattro concept car, BMW's i8 electric vehicle will feature optional laser headlamps when it goes into production this year.

In a BMW 7 Series, fitted with prototypes of the laser headlight systems, we drove through the dark French countryside to experience them for ourselves.

The results are dramatic, or should we say "enlightening". Consuming 30 per cent less energy than conventional lighting system, the laser beams have double the range: from 300 meters to 600 meters. Since many auto accidents occur at night, the ability to see further and react quicker is an important boost to safety.

BMW's system features a trio of blue lasers, which are filtered through a block of yellow phosphorous to produce a clear white light. They work with the car's onboard navigation and other systems to detect traffic and heavily settled areas, and automatically move the light to avoid blinding oncoming drivers.

Unfortunately, like Mercedes-Benz and Audi's laser systems, BMW's headlights won't yet meet North America's strict regulations.

Predictive Drivetrain Management

Since 2012, BMW has been working with its on-board navigation system to create the most fuel-efficient route possible. Predicting the road ahead, the system pre-prepares the drivetrain, so that the transmission is already in the correct gear before reaching a turn or stop and thus saving fuel.

Now they're taking it a step further. Integrating on-board cameras into the system, Predictive Drivetrain Management can sense slower moving cars ahead, and will downshift the transmission in preparation for overtaking.

On the Miramas test track, we sampled the prototype system in a BMW 5-series equipped with dash-mounted iPads displaying vehicle proximity and transmission activity. On-board cameras fore and aft help in both frontal collision avoidance, and rear blind spot monitoring.

As we followed a 3-Series around the looping circuit, the system would recognize when we drew close enough to pass, and hold the transmission in gear.

Predictive drivetrain management helps increase safety- but can also decrease fuel consumption with its more efficient transmission behaviour.

BMW invited us to their Miramas Test Facility in the south of France, to have an advance look at some of their latest technology.

|

| Photo: BMW |

CFRP Driveshaft

Lotus's Colin Chapman knew that to "go faster, you add lightness". Carbon Fibre technology is the modern day answer to the eternal quest for lightness: 30 per cent lighter than aluminum and 50 per cent lighter than steel, it's ideal for reducing vehicle weight while adding stiffness.

BMW has had the jump on carbon fibre reinforced plastic (CFRP) technology - bringing the costs down by manufacturing it themselves - with the introduction of their all-electric "i" brand. It was only a matter of time before they extended the use of this light, yet incredibly strong material throughout the rest of their lineup.

One of the most interesting items on display was a driveshaft, made entirely from CFRP - which will be introduced for the first time in the new BMW M3 sedan and M4 Coupe.

CFRP is not only extremely light - it's also renowned for its stiffness. The strength allows the driveshaft to be produced in one single component – without the weight-adding centre bearing of most conventional units.

Not only does this reduce the shaft's weight by 40 per cent, the overall reduction in rotating mass results in much quicker engine response and faster acceleration.

|

| Photo: BMW |

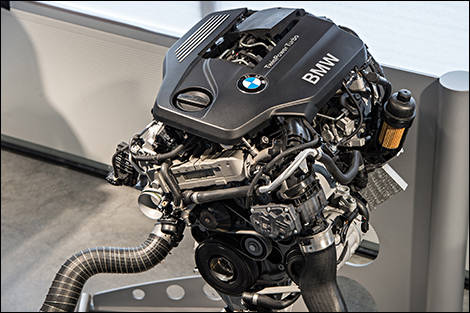

Engine Thermal Management

Developed for the new i8 electric sports car – engine thermal management will probably spread throughout the rest of the BMW lineup.

Although engines really love to breathe cool air, they function best when their body parts are kept warm. According to BMW's Intelligent Energy Management project leader, engineer Felix Schedel, engines run their most efficiently and economically when hot – yet the nature of most commutes rarely gives them the opportunity to reach that peak temperature. "The warmer the engine is at start up, the better the fuel economy will be".

Their solution was an "engine capsule" or system of various blankets formed from lightweight thermoplastic. Created of varying thicknesses depending on the job they do, these blankets cover the sides, bottom, turbo, exhaust and the gearbox and help delay the engine's cool down.

Turning over the various components in our hands, we could see the heat-reflecting foil of the thinner pieces that wrap the exhaust manifolds, with thicker, spongier capsules that encased the cooler parts of the engine.

Not only does the engine capsule help keep it at optimum temperature but it also helps reduce noise and vibration.

|

| Photo: BMW |

Laser Headlights

Between BMW and Audi, it's been a very close race to see who will be the first to market a vehicle boasting laser beam headlights. While Audi recently showed off their laser-equipped Audi Sport Quattro concept car, BMW's i8 electric vehicle will feature optional laser headlamps when it goes into production this year.

In a BMW 7 Series, fitted with prototypes of the laser headlight systems, we drove through the dark French countryside to experience them for ourselves.

The results are dramatic, or should we say "enlightening". Consuming 30 per cent less energy than conventional lighting system, the laser beams have double the range: from 300 meters to 600 meters. Since many auto accidents occur at night, the ability to see further and react quicker is an important boost to safety.

BMW's system features a trio of blue lasers, which are filtered through a block of yellow phosphorous to produce a clear white light. They work with the car's onboard navigation and other systems to detect traffic and heavily settled areas, and automatically move the light to avoid blinding oncoming drivers.

Unfortunately, like Mercedes-Benz and Audi's laser systems, BMW's headlights won't yet meet North America's strict regulations.

|

| Photo: BMW |

Predictive Drivetrain Management

Since 2012, BMW has been working with its on-board navigation system to create the most fuel-efficient route possible. Predicting the road ahead, the system pre-prepares the drivetrain, so that the transmission is already in the correct gear before reaching a turn or stop and thus saving fuel.

Now they're taking it a step further. Integrating on-board cameras into the system, Predictive Drivetrain Management can sense slower moving cars ahead, and will downshift the transmission in preparation for overtaking.

On the Miramas test track, we sampled the prototype system in a BMW 5-series equipped with dash-mounted iPads displaying vehicle proximity and transmission activity. On-board cameras fore and aft help in both frontal collision avoidance, and rear blind spot monitoring.

As we followed a 3-Series around the looping circuit, the system would recognize when we drew close enough to pass, and hold the transmission in gear.

Predictive drivetrain management helps increase safety- but can also decrease fuel consumption with its more efficient transmission behaviour.

|

| Photo: BMW |

Article Gallery