| VIDEO PRESENTATION |

Affalterbach, Germany - If I were to have a second life, I would choose to come back on Earth... as a Mercedes-AMG engine. All the care, the attention, the delicacies I would receive; that would be amazing!

|

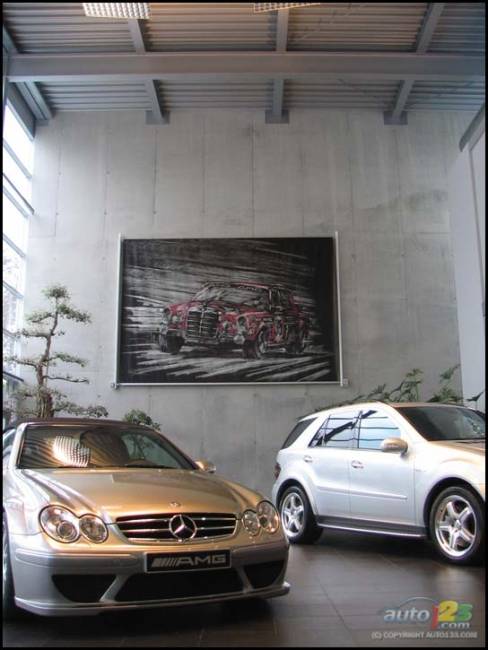

| (Photo: Nadine Filion, Auto123.com) |

Indeed, that's where Mercedes-AMG gearboxes, suspensions, brakes and other advanced components are designed, developed and manufactured. More importantly, that's also where AMG engines are assembled, even that 612-hp monster that allows a car to accelerate from 0 to 100 kph in 4.2 seconds...

The realm of performance

In a large room pleasantly bathed in sunlight, around thirty employees are working on AMG V8s, all proudly mounted on special lifts. Following the "one man, one engine" motto, each highly qualified mechanic is responsible for the entire assembly of his or her own engine -- from the positioning of the crankshaft to the very first oil filling. A total of nearly 500 components are installed by these expert hands.

|

| (Photo: Nadine Filion, Auto123.com) |

With its immaculate floor and almost religious atmosphere, the plant would have made a great monastery if it were not for the dozens of tools that hang from the roof. The noise level is negligible. One would never guess that they build nearly 20,000 engines annually (max of two engines per technician per day).

An AMG expert takes about 3.5 hours to manufacture a V8 engine. Add another hour for a V12, which is assembled on the higher floor. On this holy ground, only a dozen mechanics are at work. The atmosphere is even more "clinical" than on the main floor.

Once the engine is finished, its operation and power must be tested. Only then will the technician be able to fix a shining plaque with its own signature. According to the company, less than one percent of all engines don't make the final cut...

|

| (Photo: Nadine Filion, Auto123.com) |

That's why today's V8 and V12 engines are shipped to the various Mercedes assembly plants. The AMG integration is performed is Tuscaloosa, Alabama, for the M-, R- and GL-Class, in Graz, Austria, for the G-Class, in Sindelfingen, Germany, for the E-, CL-, CLS- and S-Class, and in Bremen, Germany, for the C-, SLK-, CLK- and SL-Class.

Still, the heart and soul of each and every AMG engine remains in Affalterbach, cradle of what can be called the German auto performance tradition.

Article Gallery