The concept of braking has been around long before the automobile was invented. Horse-drawn carriages, for instance, used basic mechanical brakes until the beginning of the 20th century, when hydraulic and air

brakes became commonplace. These systems proved to be more and more reliable throughout the years, but their numerous components (pipes, pumps, activator, control and assist devices, etc.) made them complex, heavy and costly.

But thanks to a recent invention by Germany's Bernd Gombert, Siemens VDO will most likely become the first manufacturer to offer an electronic wedge brake (EWB).

The EWB system relies on a very basic and effective principle: the wedge. Think about the small triangular piece of wood that you put under a door to prevent it from closing. Have you ever noticed that the more you push on the door, the more it resists? That's precisely what Bernd Gombert's wedge brake ingeniously takes advantage of.

How it works

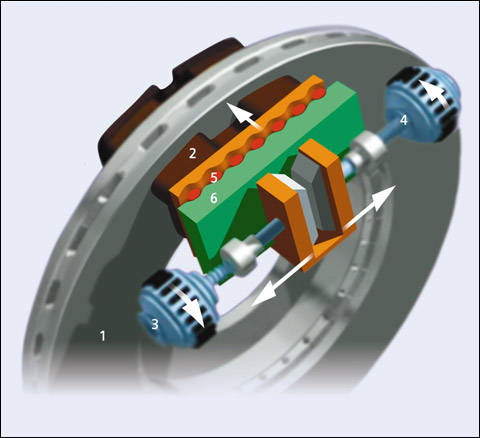

In the floating calliper of a disc brake (1), the piston and the fluid ducts are replaced by a double plate (6), slick on one side and featuring wedge-shaped "teeth" on the other. The two teethed plates face each other and lodged between the teeth are small cylindrical rollers (5). In the calliper, as with a regular brake, the rubbing pad (2) is set against the fixed, interior plate of the calliper, while the other pad (exterior) is set against the floating plate of the calliper. Two small electric motors (3 and 4) also located in the calliper move the wedges against one another. As a result, when the brake pedal is depressed, the wedges are "activated"; they push back both plates and force the pads against the disc. What's most interesting is that the wedge effect automatically increases the brake force that is applied. In reality, it's the kinetic energy of the moving vehicle that helps to slow it down. In other words, the faster the vehicle goes, the harder the brakes react.

This "mechatronic" solution that uses no hydraulic systems runs on 12-volt power. Lighter and less cumbersome than hydraulic systems, the EWB makes antilock integration easier and opens up the possibility of "differential" braking (different braking on each wheel) depending on the road and load conditions. The first few tests have shown that the EWB's performance is much more efficient than that of the best hydraulic brakes currently available.

When will the EWB hit the market? By 2010, according to Siemens VDO.

|

| (Photo: Siemens VDO) |

But thanks to a recent invention by Germany's Bernd Gombert, Siemens VDO will most likely become the first manufacturer to offer an electronic wedge brake (EWB).

The EWB system relies on a very basic and effective principle: the wedge. Think about the small triangular piece of wood that you put under a door to prevent it from closing. Have you ever noticed that the more you push on the door, the more it resists? That's precisely what Bernd Gombert's wedge brake ingeniously takes advantage of.

|

| (Photo: Siemens VDO) |

How it works

In the floating calliper of a disc brake (1), the piston and the fluid ducts are replaced by a double plate (6), slick on one side and featuring wedge-shaped "teeth" on the other. The two teethed plates face each other and lodged between the teeth are small cylindrical rollers (5). In the calliper, as with a regular brake, the rubbing pad (2) is set against the fixed, interior plate of the calliper, while the other pad (exterior) is set against the floating plate of the calliper. Two small electric motors (3 and 4) also located in the calliper move the wedges against one another. As a result, when the brake pedal is depressed, the wedges are "activated"; they push back both plates and force the pads against the disc. What's most interesting is that the wedge effect automatically increases the brake force that is applied. In reality, it's the kinetic energy of the moving vehicle that helps to slow it down. In other words, the faster the vehicle goes, the harder the brakes react.

This "mechatronic" solution that uses no hydraulic systems runs on 12-volt power. Lighter and less cumbersome than hydraulic systems, the EWB makes antilock integration easier and opens up the possibility of "differential" braking (different braking on each wheel) depending on the road and load conditions. The first few tests have shown that the EWB's performance is much more efficient than that of the best hydraulic brakes currently available.

When will the EWB hit the market? By 2010, according to Siemens VDO.