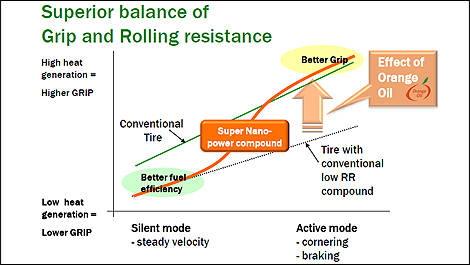

“Rolling resistance is where we play,” says Cressman. He adds that it's actually easy to achieve. “Just look at train wheels… Steels wheels, steel track… Not much rolling resistance there. The difficulty is achieving good rolling resistance while maintaining traction, safety and grip.”

Besides good rolling resistance for efficiency and grip for safety, Yokohama mandated yet another attribute for the new tire — significantly less dependence on petroleum-based products.

Organic Compounds

“A conventional tire has a high reliance on synthetic rubber, which is oil based,” says Cressman. “There is also petroleum-based carbon, which is used for filler, and polyester, which is used for the skeleton. Mix it all up, and such a tire could use as much as 40 to 50 litres of oil from start to finish… The material selection of the E-Spec is completely different.”

The tire’s main component is natural rubber, which actually has inherently lower rolling resistance than synthetic rubber. But rubber doesn’t generate the heat (via friction with the road) needed for good grip.

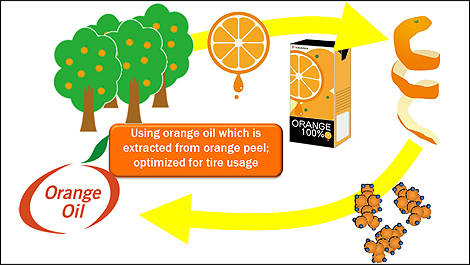

The solution involved Yokohama’s Nanotechnology, which creates the tire’s compound at a very small molecular level (one nanometer or less, which is one billionth of a metre) — and the fore-mentioned orange oil.

Orange oil and natural rubber have a similar molecular structure and are easily mixed together. Orange oil is not only a natural and sticky, it gets stickier when heated.

“When it's not working hard, the compound has the low rolling resistance of the natural rubber. As we drive more aggressively, and put more heat into it, the orange oil becomes more activated, and makes the compound behave more like a higher-grip synthetic compound.”

Other non-petroleum component includes charcoal-based carbons (for filler), and Rayon for the tire’s casing.

Note also that the tire is produced in a Japanese plant that boasts zero emissions.

|

| Photo: Yokohama |

Besides good rolling resistance for efficiency and grip for safety, Yokohama mandated yet another attribute for the new tire — significantly less dependence on petroleum-based products.

Organic Compounds

“A conventional tire has a high reliance on synthetic rubber, which is oil based,” says Cressman. “There is also petroleum-based carbon, which is used for filler, and polyester, which is used for the skeleton. Mix it all up, and such a tire could use as much as 40 to 50 litres of oil from start to finish… The material selection of the E-Spec is completely different.”

The tire’s main component is natural rubber, which actually has inherently lower rolling resistance than synthetic rubber. But rubber doesn’t generate the heat (via friction with the road) needed for good grip.

The solution involved Yokohama’s Nanotechnology, which creates the tire’s compound at a very small molecular level (one nanometer or less, which is one billionth of a metre) — and the fore-mentioned orange oil.

Orange oil and natural rubber have a similar molecular structure and are easily mixed together. Orange oil is not only a natural and sticky, it gets stickier when heated.

“When it's not working hard, the compound has the low rolling resistance of the natural rubber. As we drive more aggressively, and put more heat into it, the orange oil becomes more activated, and makes the compound behave more like a higher-grip synthetic compound.”

Other non-petroleum component includes charcoal-based carbons (for filler), and Rayon for the tire’s casing.

Note also that the tire is produced in a Japanese plant that boasts zero emissions.

|

| Photo: Yokohama |