The global pandemic is affecting just about every business sector, including the auto industry, which is taking it on the chin. For manufacturers, the situation is, simply put, catastrophic. Most factories are closed, many suppliers are at a standstill, dealerships are idle. The headwinds facing stakeholders in the auto industry are currently blowing at gale strength.

However, those stakeholders have no choice but to play the cards they’ve been dealt, and move forward as best they can. Eventually, things will get going again in terms of developing new vehicles, new technologies, concepts, etc. And when the machine starts up again, the goal – nay, necessity – will be to return to previous growth rates.

Then again, perhaps the industry will work differently, too. The crisis is serving as a lesson for everyone. Nissan, like everyone else, is having to adapt, and some of the lessons being learned may well be applicable later.

Auto123 launches Shopicar! All new makes and models and all current promotions.

Last week, the automaker invited a handful of Canadian journalists to a virtual roundtable discussion with Bob Flotkoetter, director of technology planning and research at the Nissan Technical Center North America, to discuss the current situation. A welcome opportunity for us to gain insight into what manufacturers are doing in this unique time.

In the end, six things caught our attention.

1 - Telecommuting... differently

Telecommuting is de rigueur these days, of course, and it’s easy to understand why. The concept of having employees work from home existed before, but never on the scale that it’s currently practised. When it comes to an automaker’s workforce, it’s easy to imagine several departments working from home. Think of a designer, for example, or a product planner. But what about all those who work with equipment that’s only available on site, in the factory or in the office?

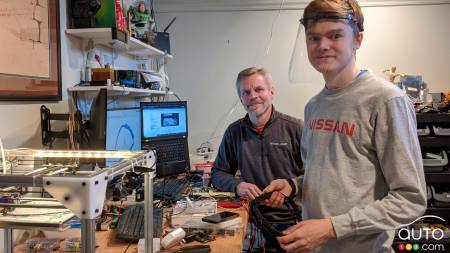

Nissan provided an enlightening anecdote. When the order came down to shut down non-essential on-site work, one of the company’s employees working on wire harnesses took the necessary equipment home with him so he could continue his work. Once he had set up a space at home to replicate his workstation, he was able to soldier on.

What will happen after the pandemic? To a large degree things should return to normal, but it’s easy to imagine companies getting creative in order to allow employees to work from home, especially in a context where social distancing will continue to be required while we await a vaccine for COVID-19. Nissan told us it already has policies in place in this regard, but that it will look at how it can improve them.

And of course, what’s valid at Nissan is valid everywhere. Companies will have to think outside the box and demonstrate both creativity and flexibility.

2 – Vehicle testing, transformed

It's not just car journalists who test-drive vehicles. Long before they reach us, teams employed by the manufacturers put their new vehicles through batteries of tests to evaluate multiple components.

At Nissan, that testing takes place mainly in the Detroit area, and it continues through the outbreak. But the pandemic has changed its nature. For one thing, rather than having two people on board the vehicles being tested, there’s only one.

One odd by-product of the current situation is that there’s one context in which automakers cannot currently test their vehicles like they normally would: high-traffic situations. The current stay-at-home measures have meant the disappearance of traffic jams in urban and suburban environments. Who would have thought such a thing possible? At least for the coming weeks, automakers will have to find new ways to carry out these evaluations.

3 - Preserving safety

When asked if it was possible for employees to travel to the office or any company facility to pick up materials in order to continue working from home, Bob Flotkoetter explained that “policies are strict about access to workplaces. It can be allowed, but only in cases of extreme necessity. The important thing is to avoid contamination of the premises.”

Indeed, in addition to the direct costs engendered by the pandemic, imagine adding to that the cost of decontaminating offices, work stations, whole factories. And beyond the cost, ensuring the safety of all workers will be a paramount concern as work environments open up again.

4 – Telecommuting: a sword with two edges

Human beings often function with entrenched habits. This is so in our home life, but it’s even more the case in the workplace. The coronavirus has turned routines upside down, and the example the folks at Nissan gave regarding their engineers got us pondering a few fundamental questions.

Bob Flotkoetter mentioned that the company’s engineers aren’t used to working on projects at home. In the office, they’re in constant communication with other departments and that's how they do their work. Yet, confined to their homes, they have no choice but to adapt the way they work. What some have found is that they work more, because their computers are always accessible. Not surprisingly, management is asking whether the practice of telecommuting might not have the net effect of increasing productivity.

Nissan's interest in the question is understandable, and it’s not to suggest the company is looking on squeezing ever-more productivity out of its workers at any cost. Rather, perhaps it’s more relevant to question the very concept of maximizing productivity. After all, one of the things confinement may be teaching us is how crazy a life we normally lead, with time always short.

Does telecommuting, which allows us to spend more time at home, have the perverse effect of making us work even more? If the practice is further encouraged after the pandemic, will it force people into working ever-longer hours? The question is worth asking and will certainly be the subject of much reflection once we return to some semblance of normal.

5 - Global interconnectedness

As we all know, factories are currently shut down and the lights are off at automakers’ offices. But Nissan, like other businesses, is doing what it can to keep development work going at normal pace. It maintains that, for the moment, there has been no change in the planning and scheduled roll-outs of new products and technologies.

That said, there’s the matter of components sourced globally that needs to be taken into account. Restarting the machine in North America implies that suppliers, wherever they are, have also resumed their activities.

The recovery, when it comes, will have to be an unprecedented coordinated undertaking. Otherwise, it will be impossible to stick to those launch schedules…

6 - What's it going to change?

We know that many things will change once "normal" life returns. We won't try to play the fortune-teller here. But already, there are some indications of changes that could be in store when it comes to vehicle design.

For example, automakers could well envision adapting interiors with materials that are easier to clean, and less conducive to the accumulation of germs or particles. Sanitation will undoubtedly be on everyone's lips when it comes to designing future models.

In the view of Bob Flotkoetter, there’s little doubt we're in for a slew of innovations, a fruit of fresh, creative thinking engendered by the coronavirus pandemic and the challenges it imposes. At this point, however, it's far too early to know what they will be.

The only thing we can be sure of is that change, there will be.