There are ten assembly lines the various components travel through, before a fully finished car finally emerges.

Although engines are imported from Mexico and Germany, they're "dressed" here; line workers add wiring harnesses and other accessories before sending them along to be mated up to transmissions and exhaust systems, and finally, bolted onto waiting frames.

Occasionally, the tinkling strains of "Itsy, Bitsy Spider" and other old folk favourites ring out. Stress-free workers have a higher-quality output, and rather than sounding a shrill alarm to warn of a malfunction on the line, a tune is played. It gets louder and more insistent until the problem's addressed.

Each stage in production, from unpainted steel shell to finished vehicle, has its own quality inspection team. Every day, 15 cars are selected at random and driven by quality control managers. There's a long track made up of several different aggregates to test the car's structural integrity over a variety of surfaces.

Instead of importing finished modules and installing them here, the entire dash is assembled in house by a department of 20 people. This way, they can keep a close eye that fitting and gaps are kept within acceptable levels.

Likewise, the on-site tooling department helps maintain a strict tolerance level. Plant manager Fischer makes special note of the Passat's "Toronado line" (inspired by the vintage Oldsmobile of that name), a sharp crease that begins with the headlights, travels along the beltline where it meets up with a line coming down from the C-pillar and continues through the taillamps. Any misalignment of this body crease would be glaringly apparent. Keeping it in-house makes it far easier to correct any errors without losing valuable production time.

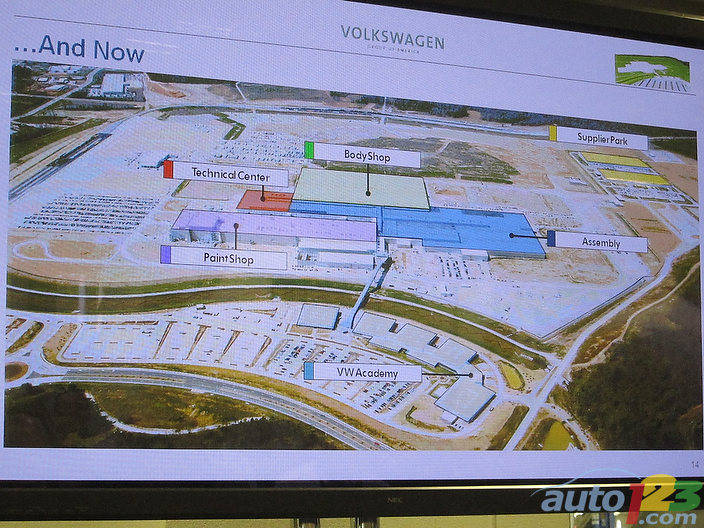

Although the company remains mum on whether there will be additional vehicles produced at this site, the plant was conceived with an eye on future adaptability. Additional paint shop cells and another shift could bring the capacity up to 250,000 vehicles with the plant's current configuration. Flipping the layout around and adding additional lines could bring the production capacity up to 500,000.

There are some strong traditional players in the mid-size market in Toyota, GM and Honda, and the competition has grown fierce with the advance of Koreans Hyundai and Kia. It's going to take a while for North Americans to think of Volkswagen as more than a niche player. Having a strong presence in the domestic market is a step in the right direction.

Although engines are imported from Mexico and Germany, they're "dressed" here; line workers add wiring harnesses and other accessories before sending them along to be mated up to transmissions and exhaust systems, and finally, bolted onto waiting frames.

Occasionally, the tinkling strains of "Itsy, Bitsy Spider" and other old folk favourites ring out. Stress-free workers have a higher-quality output, and rather than sounding a shrill alarm to warn of a malfunction on the line, a tune is played. It gets louder and more insistent until the problem's addressed.

Each stage in production, from unpainted steel shell to finished vehicle, has its own quality inspection team. Every day, 15 cars are selected at random and driven by quality control managers. There's a long track made up of several different aggregates to test the car's structural integrity over a variety of surfaces.

|

| Photo: Lesley Wimbush/Auto123.com |

Instead of importing finished modules and installing them here, the entire dash is assembled in house by a department of 20 people. This way, they can keep a close eye that fitting and gaps are kept within acceptable levels.

Likewise, the on-site tooling department helps maintain a strict tolerance level. Plant manager Fischer makes special note of the Passat's "Toronado line" (inspired by the vintage Oldsmobile of that name), a sharp crease that begins with the headlights, travels along the beltline where it meets up with a line coming down from the C-pillar and continues through the taillamps. Any misalignment of this body crease would be glaringly apparent. Keeping it in-house makes it far easier to correct any errors without losing valuable production time.

Although the company remains mum on whether there will be additional vehicles produced at this site, the plant was conceived with an eye on future adaptability. Additional paint shop cells and another shift could bring the capacity up to 250,000 vehicles with the plant's current configuration. Flipping the layout around and adding additional lines could bring the production capacity up to 500,000.

There are some strong traditional players in the mid-size market in Toyota, GM and Honda, and the competition has grown fierce with the advance of Koreans Hyundai and Kia. It's going to take a while for North Americans to think of Volkswagen as more than a niche player. Having a strong presence in the domestic market is a step in the right direction.

Article Gallery