Automakers have long dreamed of factories capable of operating without human intervention. That dream, populated by “dark factories”, in which light is useless because no one works there, now seems a little more tangible thanks to a new generation of more sophisticated robots, both autonomous and collaborative.

Gone are the static robots: Welcome AMRs, Cobots... and humanoid robots

Unlike the fixed industrial robots of the past, confined to safety cages, Autonomous Mobile Robots (AMRs) now freely patrol factory floors. These AMRs are often accompanied by cobots, collaborative robots designed to work safely alongside humans.

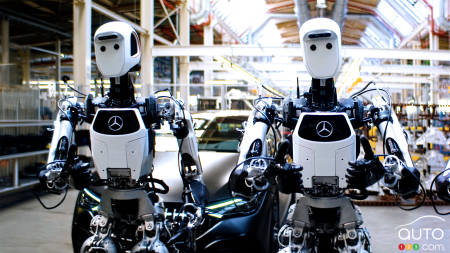

In the not-so-distant future, those machines could be supported - or replaced - by humanoid robots. Tesla, Hyundai, BMW and Mercedes-Benz are already at the forefront, experimenting with humanoids capable of lifting boxes, sorting parts and transporting components - all tasks traditionally performed by human workers.

Hyundai invests heavily in humanoid robotics

This past April, Hyundai announced an investment of $21 billion USD in its American facilities. Part of that investment will go to purchasing tens of thousands of robots from Boston Dynamics (a company in which Hyundai is the majority shareholder) within a few years. Among them will be Atlas, Boston Dynamics' iconic humanoid.

Manufacturers hope the robots will help address labour shortages while reducing production costs. For investor Cyrus Sigari, the potential is immense: “Tomorrow's dark factory could become one of the greatest competitive advantages for an automaker.”

Billions invested in humanoids

Interest in humanoids is not just the purview of Hyundai. In 2024, companies specializing in this technology received $1.2 billion USD in funding, according to CB Insights. For 2025, that influx could reach $2.3 billion.

Morgan Stanley estimates that the market could be worth $4.7 trillion USD over 25 years—twice the combined revenues of the 20 largest global automakers for the same period.

The goal is clear, but the road is long

To be sure, this is a long-term project – a marathon, not a sprint. Marie Szymanski, North American Managing Director of Industrial Assembly Solutions at Atlas Copco, points out that most of the new products presented by exhibitors at the Automate show held in Detroit last May were still collaborative robots and AMRs dominated. Humanoid robots, for now, remain largely in the developmental and experimental phases.

Automotive industry a leader in industrial robotization

The automotive sector remains the driving force behind the growth of industrial robotics. Facing challenges of reshoring, political pressures to strengthen domestic production, and a chronic labour shortage, manufacturers are relying more than ever on automation to maintain their competitiveness.

While completely dark factories don't yet exist, their outline is becoming increasingly clear... illuminated by the diodes of ever smarter robots.